Some of the more interesting air conditioners I have met

Almost all air conditioners and refrigerators on the planet work basically the same way, but some units have their own unique charms. Click on to through to see inside the thinnest, quietest, tiniest, and crappiest units I’ve ever met.

The inside of the cheapest ($99) AC I’ve ever seen. Most of the internal structure is styrofoam and the vibration dampeners are squished on plumbers putty. But it works!

The Quiet One

The Haier Serenity is “The Quietest Window Air Conditioner On The Market”…at least according to Air Conditioner Lab (and Hammacher Schlemmer until they walked it back to just “The Quiet Window Air Conditioner”). Note that I contest both these claims, but it is still interesting to look and see how they tried to reduce the noise.

I’d guess that most of the quieter-ness comes from the fact that the indoor and outdoor fans are driven by different motors. Here you can see the outside fan and motor without the typical axle that normally runs all the way to the inside fan. It is nice to see how isolated the inside section is with only the two refrigerant lines crossing the DMZ.

The DMZ between the inside and outside sections

Since the indoor fan gets its own dedicated motor, it is free to use a very nice linear cross flow blower. Also notice the little metal weights added on the fan to make sure it is perfectly balanced, just like tire balance weights.

The indoor cross flow fan with its own motor and balancing weights.

Additionally the compressor is wrapped with a dampening blanket, although this is nowhere near as effective as some of the really nicely sealed blankets I’ve seen on outdoor units. Interestingly, the blanket seems to be specifically oriented so that the openings are towards the outside.

Compressor blanket

Video tour:

The Small One

The Zero Breeze is downright tiny, and it has the cutest little compressor.

When I saw the KickStarter for this I did not think there was any chance they would ship an air conditioner at all, but they managed to build a real vapor compression cycle unit – and not a bad design either!

The most interesting thing about this unit is the compressor. It is downright tiny.

And it uses a brushless DC motor, so its speed can be controlled. Here is the speed controller board….

Unfortunately for all of its smarts, the Zero Breeze always runs the compressor at full speed. :/

Looking down at the hot side…

…we see very thoughtful service port on the left with a removable cap and some nice foam around it – maybe to prevent rattling noise?

Just south of the compressor head there is what looks like a receiver with the capillary tube wrapped around it. I don’t understand how that receiver works mounted horizontally like that. Or maybe it is not a receiver? Then what is it? If you know, please LMK in the comments!

The hot gas comes out of the compressor and gets split into two condenser coils. A nice brushless muffin sucks air over them and also past the compressor. This is likely overkill because I’ve never felt those coils even get warm. The brain board does keep this fan running for a little while after you turn the unit off to keep the compressor from overheating. Nice touch.

Here is the brain board…

…which is responsible for turning the compressor and the fans on and off, along with implementing the Bluetooth speaker and the flashlight. Wait, what?! Yep, you don’t even need this board if you just want an air conditioner that is NOT also a speaker and flashlight. I got to tell you that I’d much rather have adaptive compressor speed than a Bluetooth speaker in my air conditioner.

There is a nice centrifugal fan that sucks air through the single evaporator coil…

..and blows in onto whatever you want to cool down. This fan does have 3 speeds selectable through a button.

The whole idea of condensate collection seems to be an afterthought. When I asked them during the campaign what they were going to do with the water and and they didn’t seem to know what I was talking about. They don’t seem to mention the condensate drain anywhere on the website or in the videos, but it is there next to the power jack…

Seems like a missed opportunity since the gutter runs less than 1″ below the high side pipe – would have been so easy to have it drop down for a dip and take advantage of all that free subcooling.

Video tour:

In looking around for more info on this tiny compressor I found out that it is not even that tiny. It turns out you can get some really tiny compressors! I just ordered me one of these adorable little guys…

…from Aliexpress. I’ll let you know when it comes!

UPDATE: Awe, it’s only a baby!

I can’t wait to build a tiny little air conditioner for ants! Maybe use some old CPU coolers as the coils?

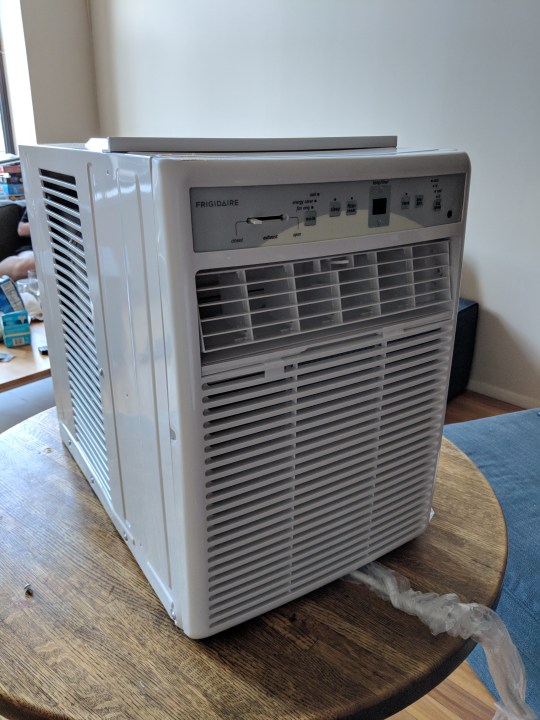

The Tall One

For those who like their cool in a tall and skinny package, casement air conditioners are well suited – but they are also expensive and loud and harder to mount.

To squeeze everything into the narrower footprint, the compressor is stacked up on a mezzanine shelf and the coils are are also split and vertically stacked.

The evaporator coil seems overly complicated with a 1:4 collection manifold.

The evaporator coil seems overly complicated with a 1:4 collection manifold.

The capillary tubes do not have the normal loop-dee-loop. Instead they go straight up and over! If you know why these tubes are different (or why normal ones always seem to have the loop) please LMK in the comments!

Unrelated to its tallness, this unit does have a nice little operable vent to let fresh air in. The outside air is pulled in by the bernoulli effect and then runs over the evaporator coil before getting blown into the conditioned space. It has a tiny little filter in there to keep outside schmutz from fouling the evaporator coils, but this filter is inaccessible so I wonder how long it would take before the fresh air inlet stops working in a dusty place.

Video tour:

The Hacked One

Once an electric company in New England thought it would be a good idea to get people to replace their electric resistance hot water heaters with heat pumps that were 2x more efficient. A lot of these heat pumps ended up on ebay. Cheap. That’s where I got mine before I hacked it into this hot cold mess…

A heat pump water heater makes cold air as a by product of making hot water. Hey wait, that’s an air conditioner!

A heat pump water heater makes cold air as a by product of making hot water. Hey wait, that’s an air conditioner!

In my apartment, the building uses a water loop connected to horrible heat pump consoles for air conditioning (the windows do not work). Those consoles are so loud that you can not sleep with one on, so I decided to hack up one of these hot water heaters to be a nice little air conditioner for my bedroom!

The most notable thing about this air conditioner is that it rejects the heat into water rather than air, so the condenser coil looks like this black spiral…

It is a pipe inside a pipe. The refrigerant runs though the inside pipe and the water runs though the outside pipe. They run in opposite directions so the cold input water first touches the liquid refrigerant right before it exits. This gives you maximum temperature difference and therefore the maximum heat transferred. This little detail would be easy to overlook, but has a huge impact on efficiency if you get it wrong.

For some reason there is a check valve on the high pressure gas line right after it comes out of the compressor (it is the little barrelly thing with the barely visible red sticker on it)….

I’ve never seen a check value here before and don’t know why you would put one there. If you know, please LMK in the comments!

Here is the evaporator coil, TXV (grey thing), and a high pressure cut-out switch (green thing)…

I have persistent problems with this evaporator icing up. Currently I use an Arduino turn off the compressor whenever the coil gets too cold. But this is a sucky solution because it cycles the compressor and is loud. I’d much rather increase the pressure in the evaporator coil to increase the boiling temp above 32F, but so far I haven’t gotten this to work. I feel like I should be able to use a heat pipe to transfer heat from the high pressure liquid right before the TXV to the low pressure gas after the evaporator coil. Would that work? Better ideas? LMK in the comments!

Video tour:

The DIY One

Built from an old refrigerator compressor, a radiator, and a beer chiller, this is almost certainly the crappiest AC unit I’ve ever met. I’m allowed to say that cause I built it.

Perhaps the only interesting thing about this unit (besides the fact that it works at all) is the metering device – it is just a plain olde ball valve. You have to manually (and constantly) adjust it to get it to try and let though the right amount of refrigerant.

It is charged with R134A which you can walk in and buy at any auto store.

Video tour:

Trainer Air Conditioner

This was built by York in the 60’s to train AC techs. All the coils are glass so you can see the refrigerant boiling and condensing. I friken love this thing. This is maybe the coolest air conditioner I have ever met and I can watch it for hours. It lives at the Refrigeration Institute of New York, where Frank has taught me many things about the vapor compression cycle!

UPDATE 11/17/2020 – Here is a great trainer video demo at HVAC School!

FAQ

Q: Why?

Because I really want to learn more about how air conditioners work. I get started learning a topic by seeing what problems other people encountered and how they solved them. You can learn even more from things that are different in some way than the normal way, since these things will tend to encounter different or more extreme problems. That’s why I look for interesting air conditioners!

Q: I meant: Why air conditioners?

Because air conditioners are really important. If you live in the developed world then you probably depend on many air conditioners (née refrigerators) for your normal daily life. They are everywhere and we often forget about how sad we would be without them.

There are a lot of people around the world who are just now coming out of poverty, and most of them live in hot places. As soon as I had enough food and a roof, then getting me an air conditioner would be one of the next things on my list. I expect a billion or so other people will feel the same way as I do.

Unlike computers and cars and cellphones and light bulbs and pretty much every other technology that is part of our lives, the insides of an air conditioner made today look pretty much the same as one made 30 years ago. We could really use some air conditioner innovation right about now!

If you are looking for the next big wave to ride, consider air conditioners. It is hard to imagine a field with more opportunity, or one where you could have more impact!

If you are already an air conditioner expert and and don’t mind answering stupid questions, then we should talk!

This was really cool, you should put the plans for your self-made a/c unit on Hackaday or make a kit out of it, I want one!

This DIY AC uses real refrigeration parts and R134A so you would have to be EPA certified to make it, but I am currently working on making one using only hardware store parts that anyone could build. It runs on isobutane which anyone can buy and use. Ideally I want to use a bike pump for the compressor, but I am having trouble getting good seals. Hopefully I will have something working to share by the end of the summer!

Nice review of the new Zero Breeze on Wired…

https://www.wired.com/review/zero-breeze-mark-ii-portable-air-conditioner

Did you end up getting to test the tiny compressor you bought? I’m keen to see how it performs in a DIY AC build!

I have it and it is very cute, but I have not had time to build anything with it yet!

Really cool comparision, thumbs up.

Regarding your questions:

the difference in capillary tubes follow an specific calulation for length (evap temp, compressor pressure and flowrate). If you change the length your evaporation temperature will change.

The check-valve on the high pressure side is just a safety measure. If your AC is off, and the room temp rises, the pressure will rise. so the compressor will have a hard time starting in this condition. We install checkvalves mostly for longlivity purposes.

the problem with the ice buildup:

first install some insulation around the “sensor” (the small thing mounted in the suction side with the copperbands) so your txv can regulate based on the real suctiontemperature and not the airflow around it.

you can take hot refrigerant and bypass your evaporator. typically this is done with hotgas (typically a bigger receiver has an hotgas out) if you take the hot liquid (it should be liquid beforr the txv) and take it to the compressor intake, you will kill it in a few months.

btw i am also working with these cheap chinese bldc compressors. They are really awesome and with speedcontrol (forget the big VFDs) you can build one awesome AC (or in my case, beercooler)

OK, this is basically what I was working on. They beat me to it. I think the bridge between the indoor and outdoor sides can be shorter than theirs, but I am guessing they went with this height to be able to use the sheet metal sides structurally to save money. They are using independent fan motors for in and out sides, and a variable speed compressor – all important and good stuff.

Have any comments on converting a window AC into a “mini-split”?

Certainly possible. You would have to take the refrigerant out, add new lines between the indoor and outdoor parts, and then refill with more refrigerant than you started.

The part of the Zero Breeze that you think might be a receiver is probably a filter-drier. To a certain extent, it will also act as a receiver due to it’s internal volume and the restriction that the capillary line provides to liquid refrigerant departing towards the evap.